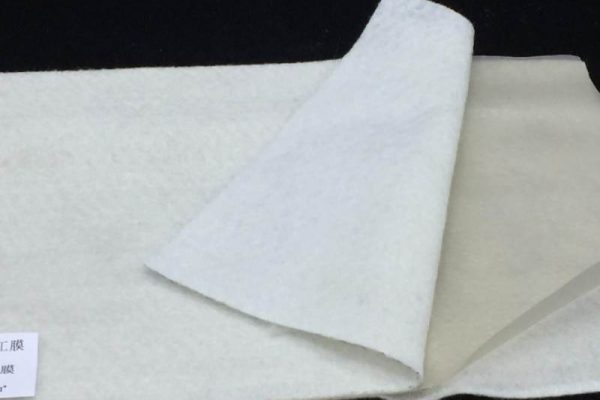

GB/T 17643-2011 GH-1 Technical Specifications

| project | indicator | ||||||||

| Thickness mm | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 密度g/cm³ | ≥ 0.94 | ||||||||

| Tensile yield strength (longitudinal and transverse) N/mm | ≥ 4 | ≥ 7 | ≥ 10 | ≥ 13 | ≥ 15 | ≥ 20 | ≥ 26 | ≥ 33 | ≥ 40 |

| Tensile fracture strength (longitudinal and transverse) N/mm | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

| Yield elongation (longitudinal and transverse)% | ≥11 | ||||||||

| Tensile elongation at break (longitudinal and transverse)% | ≥600 | ||||||||

| Right angle tear load (longitudinal and transverse)/N | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

| Anti puncture strength N | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| Carbon black content% | 2.0-3.0 | ||||||||

| Dispersibility of carbon black | Out of 10 data points, no more than 1 level 3 is allowed, and levels 4 and 5 are not allowed | ||||||||

| Atmospheric pressure oxidation induction time (OIT) min | ≥60 | ||||||||

| Low temperature impact embrittlement performance | pass | ||||||||

| Water vapor permeability coefficient g · cm/(cm2 · s · Pa) | ≤1.0x 10-13 | ||||||||

| Dimensional stability% | ±2 | ||||||||