Geomembrane

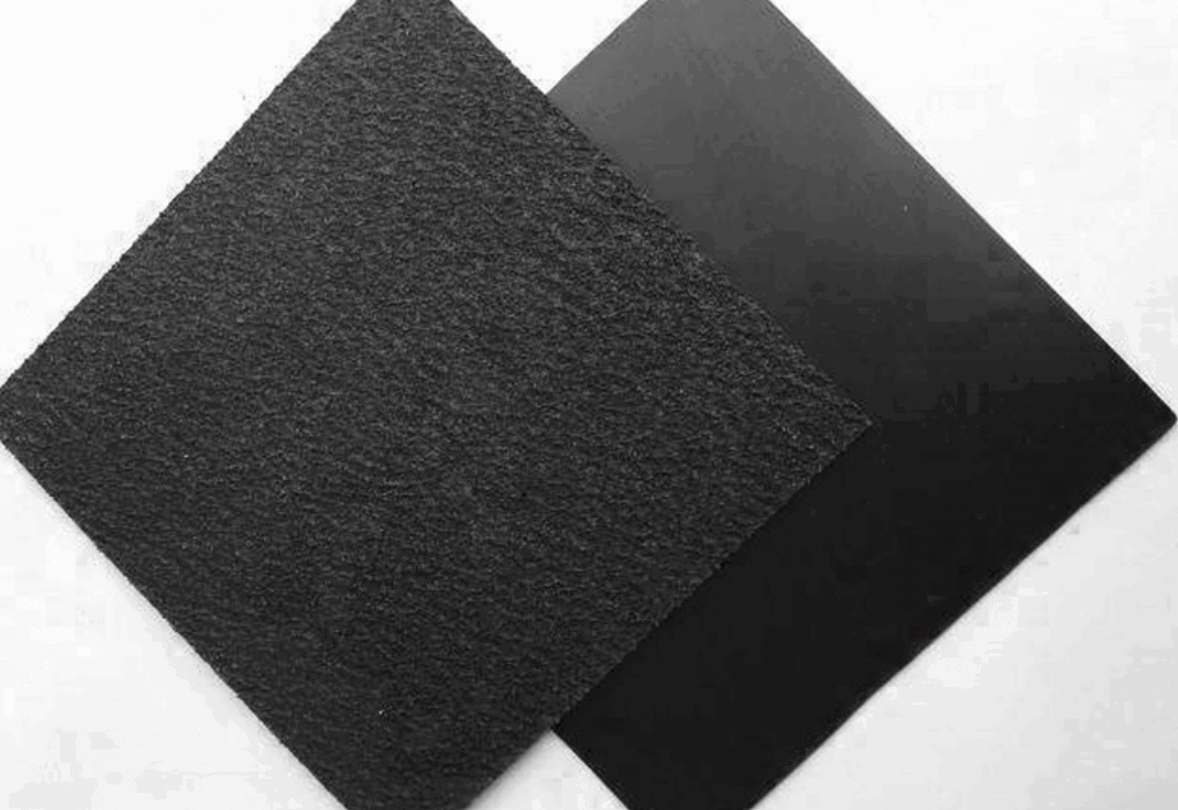

Shandong Lianjie Engineering Materials Co., Ltd. is located in the High tech Development Zone of Tai’an City. Our geomembranes include ordinary high-density polyethylene geomembranes, environmentally friendly high-density polyethylene geomembranes, and smooth HDPE geomembranes for landfill sites.Our geomembranes are mainly used for anti-seepage projects in channels, sewage treatment tanks, dock engineering, river embankments, reservoirs, lake dams, subways, garbage landfills, etc.

What is Geomembrane

Geomembrane is a geosynthetic material with functions such as anti-seepage, isolation, reinforcement, and protection. Its core function is to prevent the penetration of liquids and gases through its dense structure or special coating. At the same time, it can be combined with other geosynthetic materials to meet specific needs in engineering, and is widely used in fields such as water conservancy, environmental protection, transportation, and construction.

Price of Geomembrane

The price of geomembrane varies depending on factors such as material, thickness, production process, brand, and purchase quantity.

HDPE Geomembranes:

The price range of new-material HDPE geomembranes is relatively wide:

For a thickness of 0.5mm, the price starts at approximately RMB 2.40 per square meter;

PE Geomembranes:

The price of new-material PE geomembranes for general engineering purposes is concentrated between RMB 3.00 and RMB 15.00 per square meter.

Our Geomembrane Advantages

Customization Supported

Professional customization to meet customer needs, customers only need to provide parameters

Professional Team

Professional production team with rich experience

Advanced Technology

Professional production technology, advanced production processes

Specialized Vehicle Logistics

Strong strength and convenient transportation

Customer Evaluation of Our Geomembrane

We used this manufacturer’s geomembrane for building an agricultural water storage tank. The tested anti-seepage coefficient meets the standard, it had good ductility during laying without damage. The weld strength is sufficient, and there was no water leakage during the rainy season when storing water. It is more reliable than the products we used before, and we will choose this manufacturer for future expansion.

Michael Davis

Our waste landfill replaced with this manufacturer’s LLDPE geomembrane. It has not become brittle after two years of use, with strong puncture resistance and no damage caused by sharp garbage. The manufacturer conducts regular on-site inspections with thoughtful after-sales service, which solves the previous trouble of leachate treatment. We are very satisfied.

David Wilson

We chose this manufacturer’s environmentally friendly geomembrane for the constructed wetland project. It has a non-toxic test report, and the water quality remains clear. The customized 6-meter-wide membrane rolls reduce the number of seams and shorten the construction period. The owner recognizes the ecological effect, and we will purchase it for future landscape projects.

James Taylor

Frequently Asked Questions

What is the difference between geotextile and geomembrane?

Geotextile: Its core functions are water permeability, filtration, reinforcement, and protection. It allows water or liquids to pass through while blocking solid impurities such as soil particles and gravel, preventing the mixing of different media and enhancing soil stability.

Geomembrane: Its core functions are seepage prevention, blocking, and isolation. Its key role is to block the penetration of water or liquids, allowing almost no water to pass through. It is used to prevent leakage, pollution spread, or liquid loss.

The function and application of geomembrane

The core functions of geomembrane are seepage prevention and blocking. It can block the penetration of water or liquids and is almost impermeable to water. It has a wide range of uses, such as preventing leakage in reservoirs and water storage tanks, preventing leachate from polluting groundwater in waste landfills, preventing the penetration of chemical liquids in chemical storage yards, and it can also be used in projects such as salt isolation in saline-alkali land.

How to install geomembrane?

The installation of geomembrane must strictly comply with the Technical Code for Application of Geosynthetic Materials (GB/T 50290-2014) and product technical requirements. It mainly centers on five core links: “foundation control → membrane laying → connection and reinforcement → quality verification → protective backfilling”. The key professional points are as follows:

1. Foundation Pre-treatment (Core Premise)

Foundation Cleaning: Thoroughly remove gravel, grass roots, sharp debris (hard objects with particle size > 5mm must be eliminated) from the construction surface to prevent membrane puncture. For local potholes, level them with graded sand and gravel (silt content < 3%), and ensure the compaction degree reaches over 93% (light compaction standard).

Slope Treatment: When the slope gradient > 1:2.5, anti-slip steps (width 30-50cm, height 15-20cm) shall be built; for vertical slopes, anchor trenches (depth 50cm, width 40cm) shall be set, and graded sand and gravel shall be filled in the trenches to prevent membrane sliding.

Protective Layer Laying: If the foundation is a rigid interface such as sand-gravel or concrete, first lay short-fiber needle-punched geotextile with weight ≥ 300g/m² (lap width 15cm) as a membrane buffer layer to avoid direct friction damage between the membrane and the rigid foundation.

2. Membrane Laying (Key Control)

Laying Direction: Priority shall be given to laying along the long-axis direction of the terrain to reduce the number of joints. When laying on slopes, unfold the membrane from top to bottom; dragging from the bottom of the slope is prohibited to avoid membrane stretching and deformation (elongation rate shall be controlled within 5%).

Slack Control: Reserve slack according to ambient temperature – 3%-5% reserve at 20-30℃, and 8%-10% reserve when temperature < 10℃ – to prevent weld cracking due to low-temperature shrinkage. After laying, temporarily fix the membrane with sandbags (15-20kg per bag) at intervals of 2-3m to avoid displacement by wind.

Lap Requirements: The flat lap width ≥ 10cm, and the slope lap width ≥ 15cm; joints of adjacent membrane rolls shall be staggered (staggered distance ≥ 50cm), and “cross-shaped” joints are prohibited to reduce leakage risks.

3. Connection and Reinforcement (Core Process)

Welding Process (Mainstream Method for HDPE/LDPE Membranes)

Equipment Selection: Use a double-track hot-melt welding machine (welding temperature 180-220℃, traveling speed 1.5-2.5m/min), with a hot air gun for edge treatment. When the membrane thickness > 1.5mm, double-track welding shall be adopted (weld width 10-15mm, with a detection air channel left in the middle).

Pre-welding Test: Before formal construction of each batch, conduct a test weld under the same working conditions (test weld length ≥ 1m), and start formal construction only after passing the tensile test (weld tensile strength ≥ 80% of the base material).

Bonding Process (For Flexible Membranes Such as EVA/ECB)

Use special two-component polyurethane adhesive (curing time 24h). First, clean the lap surface (wipe with acetone to remove dirt), apply adhesive with thickness 0.8-1.2mm, let it stand for 5-10min, then bond and roll repeatedly with a rubber roller (pressure 0.3-0.5MPa) to ensure no air bubbles in the adhesive layer.

4. Quality Verification (Mandatory Inspection Link)

Weld Inspection: Adopt the “air inflation test method” for double-track welds – insert the test needle into the weld air channel, inflate to 0.25MPa, and maintain pressure for 5min; a pressure drop ≤ 0.02MPa is qualified. For single-track or bonded joints, use the “vacuum test method” – cover the joint with a vacuum hood (negative pressure 0.02MPa), and no air bubbles observed is qualified.

Appearance Inspection: Check that the membrane has no damage or wrinkles (local wrinkle area ≤ 0.2m²), no edge warping or degumming at joints, and the membrane in the anchor trench is firmly fixed (no loosening).

Sampling Inspection: Randomly select 3 joints per 1000m² for tensile testing; if unqualified, double the sampling volume; if still unqualified, rework the joints of this batch.

5. Protection and Backfilling (Final Guarantee)

Temporary Protection: Complete covering within 24h after the laid membrane passes inspection; the exposure time ≤ 48h (to avoid UV aging). Use geotextile with weight ≥ 500g/m² for temporary covering, fixed at intervals of 1.5m.

Backfilling Requirements: Backfill with fine-grained soil (particle size < 20mm, silt content 15%-25%), in layers (each layer thickness 20-30cm), with compaction degree ≥ 90%. Heavy machinery is prohibited from directly rolling the membrane during backfilling; first compact the surface soil with a light roller (≤ 5t), then use heavy machinery for operation.

Anchorage Treatment: Fill the anchor trench with graded sand and gravel (compaction degree 93%), and seal the top with a concrete cover plate (thickness 10cm) to prevent membrane falling off due to rainwater scouring.

Latest Blog Posts

Concrete Fabric: Types, Applications, Installation & Purchasing Guide

In infrastructure construction, slope protection, waterproofing, temporary works and other scenarios, Concrete

Filter Fabric Geotextile: Price, Types, Applications

As a core category of geosynthetic materials, Filter Fabric Geotextile is a

Geotextile for Soil Stabilization: Principles, Types and Application Scenarios

In infrastructure projects such as roads, slopes, dams and soft soil foundations,

Geotextile Fabric for Waterproofing: Benefits, Types, Applications and Selection

In civil engineering, water conservancy construction, environmental governance and other fields, waterproof

Geotextile Fabric for Septic Systems

For households or commercial establishments with independent septic systems, clogging, poor drainage,

Does Geotextile Fabric Stop Weeds?

In fields such as agricultural cultivation, landscaping, and road maintenance, weed infestation

Concrete Geotextile: Types, Price, Applications, Selection & Installation

In the field of civil engineering, Concrete Geotextile, as a key geosynthetic

Pros and Cons of Landscape Fabric Under Gravel

Gravel is widely used in landscape renovation scenarios such as patio paths,