A failed filtration system can lead to roadbed settlement,embankment instability,or drainage system clogging,resulting in significant engineering risks and economic losses.As a critical material in modern geotechnical engineering,the core function of geotextile filter cloth is to achieve stable and efficient soil-water separation.This article serves as a systematic guide to explain what geotextile filter fabric is,its applications,and how to select the right type.

I.What is Geotextile Filter Cloth?

Geotextile filter cloth is a permeable synthetic material specifically designed for geotechnical engineering.Its core function is to achieve the principle of being”permeable to water but impermeable to soil”,addressing filtration and drainage problems in engineering projects.

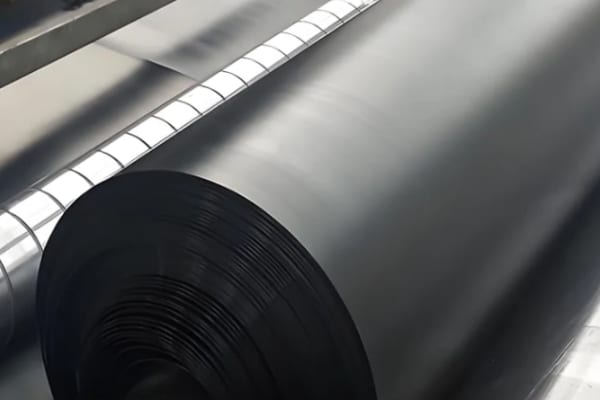

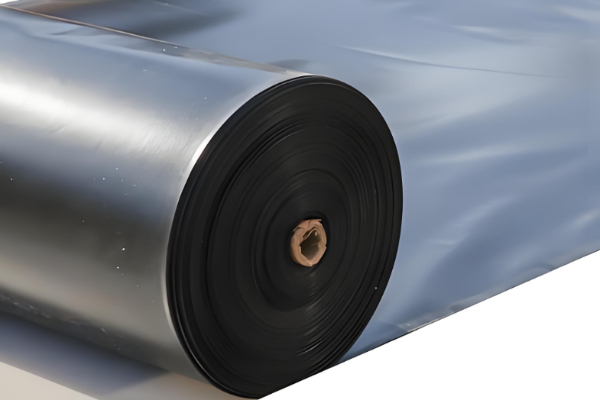

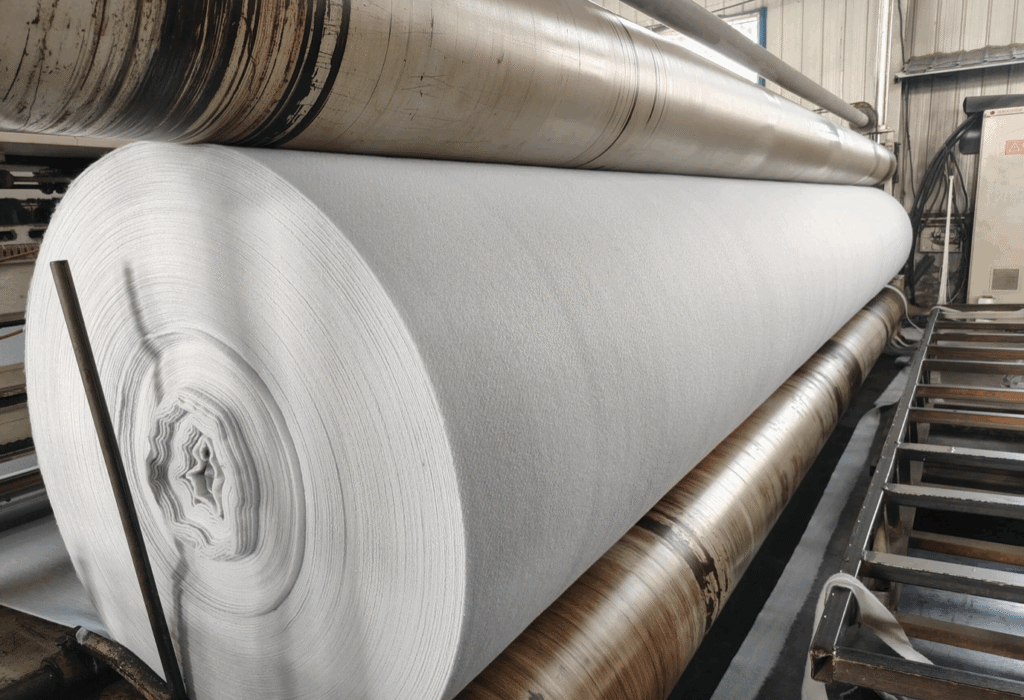

It is primarily made from polypropylene or polyester via needle-punching(non-woven)or weaving processes,possessing excellent corrosion resistance and aging durability.In engineering applications,it is placed between soil and drainage aggregate(e.g.,gravel).Its working principle is not simple sieving but rather a dynamic filtration mechanism:as water flows through,soil particles form a stable”filter cake”at the fabric’s pore openings.This layer works synergistically with the geotextile,allowing water to pass freely while effectively preventing soil particle loss,thereby maintaining the long-term effectiveness of the drainage system.

If you are purchasing Geotextile Filter Cloth, you can contact us!

II.Is Filter Fabric the Same as Geotextile?

Not exactly the same,but they are closely related.A simple analogy can help understand the relationship:

“Geotextile“is a broad category,similar to”vehicle”.

“Filter fabric”specifies its primary function,just like a”truck”is a vehicle designed specifically for transportation.

Therefore,all geotextiles used for filtration can be called geotextile filter fabrics,but not all geotextiles are primarily designed for filtration(e.g.,some focus on reinforcement or separation).This guide discusses precisely those geotextiles designed for high-performance filtration applications.

III.What is Geotextile Filter Cloth Used for?

Road and Railway Subgrade Drainage: Installed between the subgrade and the gravel layer to prevent fine soil particles from invading and clogging the drainage layer,ensuring efficient water discharge and extending the road’s service life.

Landfills and Erosion Control: Acts as a filter layer in leachate collection systems in landfills;prevents soil erosion from water flow on riverbanks and coastlines while allowing water penetration.

Retaining Walls and Drainage Ditches: Placed behind retaining walls to allow rapid drainage of accumulated water,significantly reducing hydrostatic pressure and ensuring structural stability.

Sports Fields and Landscaping Projects: Provides subsurface drainage for lawns,playgrounds,etc.,preventing waterlogging and ensuring site performance and safety.

IV.How Does Geotextile Filter Cloth Work?

The filtration process of geotextiles is not simple”sieving”but a dynamic engineering process.The principle is as follows:

As water passes through the geotextile,fine soil particles undergo a”bridging”phenomenon near its surface,forming a denser”filter cake.”This cake itself becomes an efficient filtering layer,allowing water to pass while preventing further soil particle loss,thus achieving a stable state of being permeable to water but not to soil.The design must adhere to strict filtration criteria to ensure the fabric’s pore size matches the gradation of the soil particles.

V.How to Select the Right Geotextile Filter Cloth?

Selecting the correct geotextile filter cloth for a project requires attention to the following core parameters:

Equivalent Opening Size(AOS/O95): This is the most critical parameter.It indicates the pore size of the geotextile and must be selected based on the particle size distribution curve of the soil being protected to ensure neither excessive soil loss nor clogging occurs.

Permittivity/Hydraulic Conductivity: A key indicator measuring the water conductivity of the geotextile itself.It must be significantly higher than the permeability of the surrounding soil to ensure unimpeded drainage.

Mechanical Properties(Tensile Strength,Puncture Resistance,Tear Strength): Ensure the fabric can withstand various loads during installation and long-term use without failure.

Mass Per Unit Area(Weight): Often related to thickness and durability,it is a basic indicator for measuring product specifications.

VI.Woven vs.Non-Woven Geotextile Filter Cloth

| Characteristic | Non-Woven Geotextile Filter Fabric | Woven Geotextile Filter Fabric |

| Manufacturing Process & Structure | Fibers are randomly arranged and entangled through needle-punching, forming a three-dimensional network structure. | Filaments or tapes are interlaced in perpendicular directions (warp and weft), creating a regular, two-dimensional planar structure. |

| Key Properties | Excellent contaminant retention capacity and high in-plane water flow capacity (transmissivity). High elongation. | High tensile strength and modulus, stable and uniform opening sizes. Low elongation. |

| Filtration Mechanism | Bulk filtration throughout the fabric’s thickness. | Surface filtration, acting like a sieve. |

| Typical Applications | Road subgrade drainage, landfill leachate collection systems, embankment drainage, erosion control. | Filtration scenarios requiring high strength, such as reinforced filtration layers in soft ground improvement and drainage behind reinforced retaining walls. |

Conclusion

In summary,geotextile filter cloth is far more than a simple piece of”cloth”;it is a critical functional component based on precise geotechnical engineering design.Correctly understanding its”permeable to water but impermeable to soil”principle,mastering the key selection parameters such as Equivalent Opening Size(AOS)and permeability,and making informed choices between woven and non-woven types based on specific application scenarios(e.g.,drainage,filtration,reinforcement)are essential for ensuring the long-term safety and cost-effectiveness of engineering projects.

If you are looking for a reliable Geotextile Filter Cloth supplier,please feel free to contact us.

About Us:Lianjie

Lianjie is a one-stop supplier of geosynthetics with 15 years of professional experience and multiple national certifications.We provide the most professional Geotextile Filter Cloth solutions!

Reference Sources

- ASTM D4439 – Standard Terminology for Geosynthetics

- Purpose of Citation: Provides standard definitions for terms like “geotextile” and “filter fabric,” ensuring terminological accuracy and international consistency. This is the foundation for answering “What is a geotextile filter fabric?” and clarifying concepts.

- ASTM D4751 – Standard Test Method for Determining Apparent Opening Size (AOS) of a Geotextile

- Purpose of Citation: Provides the standard testing method for the core parameter “Apparent Opening Size (AOS),” enhancing the authority of AOS data presented.

- ASTM D4491 – Standard Test Methods for Water Permeability of Geotextiles by Permittivity

- Purpose of Citation: Supports the testing standard for the key selection parameter “Permittivity/Hydraulic Conductivity,” indicating that our recommendations follow scientific measurement methods.