French drain systems are an effective engineering solution for resolving yard waterlogging,slope drainage,and foundation damp-proofing.However,premature failure of many systems is not due to poor design but rather the wrong choice of core filtration material.Wrapping the drainage gravel with an incorrect geotextile can lead to rapid clogging within months,rendering the drainage system ineffective.

This article provides an in-depth analysis of why non woven geotextile is globally recommended by engineers as the ideal choice for French drains,and guide you on how to choose the correct specification of non-woven geotextile for French drainage according to project requirements and ensure correct installation for long-term performance.

Why is Non Woven Geotextile the Ideal Choice for French Drains?

The core functions of a French drain system are”filtration”and”drainage.”Non woven geotextile plays an indispensable role as an”intelligent filter.”

Structural Advantages of Non Woven(Needle-Punched)Geotextile: Its manufacturing process involves randomly arranged fibers that are mechanically entangled through needle-punching,creating a complex three-dimensional network structure.This structure,similar to”felt wool,”offers key characteristics:

Surface Filtration Mechanism: Water can flow through smoothly,while soil particles are effectively blocked on the geotextile’s surface,forming a filter cake.This mechanism effectively prevents fine particles from entering the drainage core,significantly reducing the risk of internal clogging.

Excellent Permeability: The three-dimensional structure provides ample void space,ensuring water can flow quickly both in the planar direction(within the geotextile plane)and vertically through it.

Comparison with Woven Geotextile: The structure of woven geotextile is similar to”canvas,”with regular and relatively uniform pores.Under soil pressure,fine particles can easily penetrate and clog these pores(a phenomenon known as”piping”),or form a mud cake on the pores,leading to a rapid decrease in permeability.Therefore,woven geotextiles are more suitable for applications requiring high-strength separation and reinforcement,such as constructing temporary access roads or stabilizing soft subgrades,rather than as filter materials in drainage systems.

Conclusion: The three-dimensional network structure of non woven geotextile provides superior anti-clogging performance and consistent permeability,which are the lifelines for the long-term effectiveness of a French drain system.

If you are purchasing Non Woven Geotextile for French Drains, you can contact us!

How to Choose the Right Non Woven Geotextile for Your French Drain?

Selecting the correct specifications is key to ensuring a cost-effective project.As a manufacturer,we recommend focusing on the following core indicators:

1.Weight(Mass per Unit Area-g/m²)

This is a key indicator of the geotextile’s mass per unit area,directly related to its thickness and mechanical properties.

Standard Grade(120-150 g/m²): Suitable for most residential yard drainage,landscape drainage,and other scenarios with low load requirements.This specification offers a good balance between filtration performance and cost.

Medium Strength(200-250 g/m²): Suitable for projects like drainage beside driveways,sports field drainage,and road slope drainage that may bear larger static or dynamic loads.A higher weight means a thicker structure with better puncture resistance and durability.

Heavy-Duty Grade(300 g/m²and above): Used for large-scale municipal projects,drainage layers in landfills,and drainage for heavy retaining walls under extreme conditions.

2.Mechanical Properties(Following ASTM International Standards)

Tensile Strength(ASTM D4632):Measures the geotextile’s ability to resist pulling forces during installation and backfilling.Insufficient strength can lead to tearing during construction.

Tear Strength(ASTM D4533):Measures the geotextile’s resistance to the propagation of a rip,especially important in soil environments containing sharp stones.

CBR Puncture Strength(ASTM D6241):Simulates the geotextile’s resistance to puncture from concentrated loads(like sharp gravel corners).

Purchasing Advice:Always request the product’s technical data sheet from the supplier and verify that the above indicators meet your project’s design requirements.

3.Hydraulic Properties

Apparent Opening Size(AOS-ASTM D4751): Indicates the size of the pores in the geotextile.For filtration applications,typically choose an AOS value≤the soil’s characteristic particle size d₈₅to achieve the”retain soil,pass water”effect.

Permittivity/Permeability(ASTM D4491): Directly reflects the water flow capacity through the geotextile.

How to choose the right non-woven geotextile for your project

Residential Yard/Landscape Drainage->Recommendation: 120-150 g/m²Standard Non Woven,focus on permeability.

Commercial Project/Driveway Drainage->Recommendation: 200-250 g/m²Medium-Strength Non Woven,verify CBR Puncture and Tensile Strength.

Large Project/Heavy-Duty Application->Recommendation: 300 g/m²and above Heavy-Duty Non Woven,require full set of mechanical&hydraulic properties to meet design specs.

Non Woven Geotextile for Your French Drain Professional Installation Steps

Incorrect installation can ruin the highest quality geotextile.Please follow these professional installation steps:

Excavate Trench: Excavate according to the design slope,ensuring the trench bottom is level and firm.Remove sharp debris.

Lay Geotextile: Place the non woven geotextile along the bottom and sides of the trench.Ensure the geotextile is wide enough to fully envelop the gravel layer,with ample overlap width(typically 30-50 cm).

Place Drainage Pipe and Gravel: Position the perforated drainage pipe in the center of the trench.Then,fill with clean,washed graded gravel(typically 20-40mm diameter)up to the design height.

Envelop and Overlap: Fold the sides of the geotextile up and over to completely envelop the gravel layer.Ensure the overlapping sections are tight;secure them with specialized adhesive or stitching to prevent soil intrusion.

Backfill: Proceed with the final backfill.Avoid operating heavy machinery directly on the exposed geotextile.

Common Mistakes to Avoid:

Error: Using common weed barrier fabric instead of engineering-grade geotextile.

Error: Insufficient geotextile overlap width or failure to secure the overlap.

Error: Backfill soil containing large,sharp objects that can puncture the geotextile.

Engineering-Grade Solutions:The Advantage of Choosing a Specialist Manufacturer

For engineers,contractors,and owners who prioritize project quality and long-term value,sourcing directly from a specialist manufacturer provides a higher level of assurance.

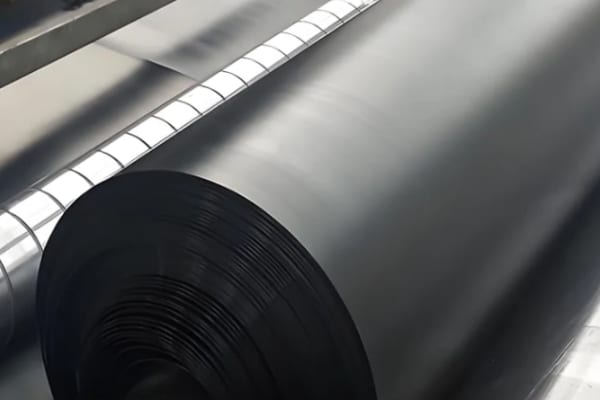

Controlled Quality: Strict quality control from raw materials(polyester/polypropylene)to finished product ensures consistent performance roll after roll,supported by complete quality inspection reports.

Comprehensive Specifications&Customization: We offer a full range of products from 120 g/m²to 800 g/m²,and can customize width and length based on project needs,reducing waste and optimizing costs.

Professional Technical Support: Our engineering team provides free technical consultation,from material selection to installation considerations,safeguarding your project.

Scale and Cost-Effectiveness: Direct factory supply,eliminating intermediary margins,offers highly competitive pricing and stable supply assurance,especially for large projects.

If you are looking for a reliable non woven geotextile fabric for french drain supplier,please feel free to contact us.

About Us:Lianjie

Lianjie is a one-stop supplier of geosynthetics with 15 years of professional experience and multiple national certifications.We provide the most professional non woven geotextile fabric for french drain solutions!

Conclusion

Selecting non woven geotextile for a French drain system is not merely a material purchase but a critical technical decision impacting the project’s service life.Understanding its working principle,selecting specifications scientifically based on the project,and strictly adhering to installation specifications are fundamental to ensuring a long-term return on investment.

References:

- ASTM D4632 – Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method

- Application in Article: The “Mechanical Properties” section.

- Explanation: This is the most fundamental and important standard for measuring the mechanical properties of geotextiles. Referencing it demonstrates that our control over key product indicators adheres to international norms.

- ASTM D6241 – Standard Test Method for Measuring the Puncture Resistance of Geotextiles

- Application in Article: The “Mechanical Properties” section (CBR Puncture Strength).

- Explanation: This test directly simulates the puncture of geotextiles by sharp gravel corners, making it highly relevant to the French drain application and strengthening the scientific basis of our selection advice.

- ASTM D4751 – Standard Test Method for Determining the Apparent Opening Size (AOS) of a Geotextile

- Application in Article: The “Hydraulic Properties” section.

- Explanation: AOS is a core parameter in filter design. Mentioning this standard and linking it to soil particle size (d₈₅) demonstrates our professional depth in understanding the filtration mechanism.