- What is Non-Woven Geotextile Fabric?

- Types,Materials,and Key Characteristics of Non-Woven Geotextile Fabric

- Primary Application Areas of Non-Woven Geotextile Fabric

- How to Choose the Right Non-Woven Geotextile Fabric?

- Brief Guidelines for Installation and Construction

- Market Trends and Future Prospects for Non-Woven Geotextile Fabric

- Frequently Asked Questions(FAQ)

- Conclusion

Beneath roads,within slopes,and inside drainage ditches,there is a material that,while inconspicuous,is crucial for ensuring engineering safety,durability,and stability—Non-Woven Geotextile Fabric.Whether addressing challenging soil separation issues or designing efficient drainage systems,this versatile synthetic material plays an irreplaceable role.This article provides a comprehensive analysis of non-woven geotextile fabric,from fundamental principles to practical applications,assisting you in making the most informed choices for your next project.

What is Non-Woven Geotextile Fabric?

Non-woven geotextile fabric is a permeable fabric-like material composed of synthetic fibers(primarily polypropylene or polyester)randomly arranged through processes such as needle-punching,heat-bonding,or chemical bonding.Unlike woven geotextiles made from interlaced yarns,its fibers form a disordered structure with numerous tiny pores,granting it excellent filtration and drainage performance.

Its core functions can be summarized into the following five points:

Separation:Prevents different types of soils or materials(e.g.,subgrade and base course)from mixing,maintaining the integrity and function of each layer.This effectively avoids the intermingling of materials with different particle sizes,ensuring the design performance of structural layers.

Filtration:Allows water to pass through smoothly while effectively retaining and stabilizing soil particles,preventing the loss of fine-grained soil.This characteristic of permeability and soil retention is key to its application in drainage systems.

Drainage:Collects and directs water flow along its plane,providing efficient drainage for engineering projects.Its three-dimensional fiber structure forms continuous water flow channels,effectively removing excess pore water.

Reinforcement:Disperses loads through its tensile strength,enhancing the shear strength and overall stability of soil.It is commonly used for reinforcing soft foundations and slopes.The friction interaction between the geotextile and soil improves the mechanical properties of the soil.

Protection:Acts as a cushioning layer,reducing the risk of damage to other impermeable materials(e.g.,geomembranes)under pressure or during backfilling.By dispersing stress,it protects waterproofing layers from puncture by sharp objects.

These functions are often not isolated;in practical engineering,two or more functions frequently work simultaneously to address geotechnical challenges.

Types,Materials,and Key Characteristics of Non-Woven Geotextile Fabric

1、Primary Materials

Polypropylene(PP):The most common choice,offering good chemical corrosion resistance and cost-effectiveness,suitable for most conventional environments.

Polyester(PET):Provides higher strength and creep resistance,making it ideal for heavy-duty projects requiring long-term performance.

2、Manufacturing Processes

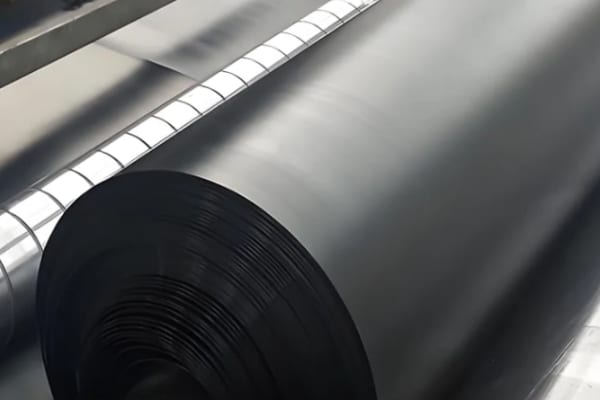

Needle-Punched Non-Woven Geotextile:The most prevalent type,produced by mechanically entangling fibers with barbed needles.The product is soft,isotropic,and suitable for various applications.

Heat-Bonded Non-Woven Geotextile:Created by heating the fiber web to partially melt and bond the fibers.The product is typically thinner,stiffer,and offers higher strength.

3、Key Characteristics and Advantages

Physical Properties:Unit area mass(g/m²,e.g.,100g/m²,200g/m²),thickness,tensile strength,tear strength,and puncture resistance.These indicators directly determine its reinforcement and protective capabilities.

Hydraulic Properties:Apparent Opening Size(AOS)and vertical permeability coefficient.These are critical parameters for evaluating its filtration and drainage efficiency.

Durability:UV resistance,chemical corrosion resistance,and biodegradation resistance ensure long-term service life.

Key Advantages:Versatility,ease of installation,cost-effectiveness,and uniform quality stability.

Primary Application Areas of Non-Woven Geotextile Fabric

The applications of non-woven geotextile fabric are extensive,supporting its market share(projected to grow steadily from approximately RMB 26.7 billion in 2023).

Road and Railway Construction:This is its largest application area.Used for separation and stabilization of subgrades and ballast,it effectively prevents soft soil upheaval and stone sinking,significantly extending road lifespan and reducing maintenance costs.

Drainage Systems:Serves as a wrapped filter layer around geotechnical drainage pipes and ditches,preventing soil particles from clogging the drainage system and maintaining long-term effectiveness.

Erosion Control and Slope Stabilization:Used in slope protection projects for riverbanks,coastlines,and hillsides to prevent soil erosion.It can be combined with vegetation to create ecological slopes.

Landfills and Environmental Engineering:Used in leachate collection systems and final cover layers of landfills as a filtration and protective layer.

Agriculture and Horticulture:Functions as a weed suppression fabric,allowing water penetration while inhibiting weed growth.It can also be used for ground management in nurseries and greenhouses.

How to Choose the Right Non-Woven Geotextile Fabric?

Selecting the appropriate product is critical.Key considerations include:

Define Design Function:Determine the primary project requirement—separation,filtration,drainage,or reinforcement.This will dictate the product’s focus.

Soil Conditions:The type of soil(cohesive or sandy)and particle size determine the required Apparent Opening Size(AOS)of the geotextile to ensure effective filtration(balancing soil retention and water permeability).

Load Conditions:The magnitude of expected static or dynamic loads determines the required tensile strength,tear strength,and puncture resistance of the product.

Environmental Exposure:Consider whether UV resistance(e.g.,short-term exposure during construction),chemical corrosion resistance(e.g.,landfill environments),or biodegradation resistance is needed.

A brief comparison with non-woven geotextiles:

When choosing, one often struggles with non-woven and woven geotextiles. Here are their core differences:

| feature | nonwoven geotextiles | Woven geotextile |

| Main functions | Separation, filtration, and drainage | Reinforcement and stability |

| permeability | High (water can easily pass through the plane and thickness direction) | Moderate (water mainly flows in the plane direction) |

| tensile strength | Medium to high (isotropic) | Very high (anisotropy, high intensity along the latitude and longitude directions) |

| adaptability | High (high elongation, able to adapt to larger deformations) | Low (low elongation) |

Simply put, non-woven fabric is required for drainage filtration, and high-strength reinforcement is required for weaving.

If you are purchasing non-woven geotextiles, you can contact us

Brief Guidelines for Installation and Construction

Site Preparation:The base layer should be leveled and compacted,with roots,sharp stones,and other尖锐objects removed to prevent puncturing the geotextile.

Installation:The overlap method is typically used,with an overlap width generally ranging from 30 to 100 cm,depending on the application and load.On slopes,installation should proceed from top to bottom.

Backfilling:Backfill material should be carefully placed,starting from a low height to avoid direct impact on the geotextile.Machinery such as bulldozers should operate directly on the backfill material,avoiding direct碾压of the geotextile.

Compliance with Specifications:Always adhere to project design specifications and the manufacturer’s construction guidelines.

Market Trends and Future Prospects for Non-Woven Geotextile Fabric

The non-woven geotextile fabric market is steadily growing,driven by global infrastructure investment and increasing environmental awareness.Future trends include:

Sustainable Development:Use of environmentally friendly materials such as recycled polyester(rPET)to produce geotextiles.

Technological Innovation:Development of higher-performance,more durable fibers,and”smart geotextiles”integrated with sensors for health monitoring.

Expansion of Application Areas:Playing a greater role in new fields such as green infrastructure,sponge city construction,and tailings treatment.

Frequently Asked Questions(FAQ)

Q1:What is the typical service life of non-woven geotextile fabric?

A:Under design loads and proper installation conditions(avoiding direct UV exposure),its service life can exceed 25 years or even 100 years.Polyester materials generally offer better creep resistance than polypropylene.

Q2:Can it be directly used in asphalt overlay(asphalt paving)?

A:Yes,this is a common application known as a stress-absorbing layer or anti-reflective cracking layer.It absorbs and disperses stress at cracks,delaying the appearance of reflective cracks and extending pavement life.Specially heat-bonded or surface-treated non-woven geotextiles must be used.

Conclusion

Although seemingly simple,non-woven geotextile fabric is an indispensable multifunctional material in modern geotechnical engineering.From stabilizing the roads we travel on to protecting the soil and water environments we rely on,its value is ubiquitous.The key to successful application lies in a deep understanding of project requirements and selecting products with appropriate physical and hydraulic properties.We hope this guide provides a solid knowledge foundation for your project planning and material selection.

Reference Sources

- ISO 10318:Geosynthetics-Terms and definitions.

- ISO 9862:Geosynthetics-Sampling and preparation of test specimens.

- ASTM D4439:Standard Terminology for Geosynthetics.

- ASTM D6241:Standard Test Method for the Static Puncture Strength of Geotextiles and Geotextile-Related Products Using a 50-mm Probe.

If you are looking for a reliable non-woven geotextile fabric supplier,please feel free to contact us.

About Us:Lianjie

Lianjie is a one-stop supplier of geosynthetics with 15 years of professional experience and multiple national certifications.We provide the most professional Non Woven Geotextile Fabric solutions!