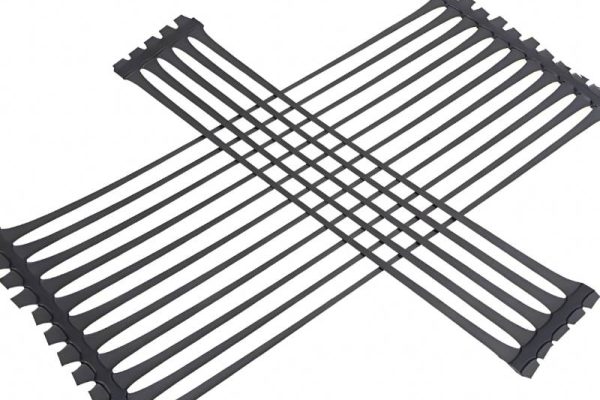

Biaxial Geogrid Product Specification and Performance Table GB/T17689-2008

| project | TGSG15-15 | TGSG20-20 | TGSG25-25 | TGSG30-30 | TGSG35-35 | TGSG40-40 | TGSG45-45 | TGSG50-50 |

| Longitudinal tensile yield strength per linear meter KN/m | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| Lateral tensile yield strength per linear meter KN/m | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| Longitudinal yield elongation ≤% | 15 | |||||||

| Lateral yield elongation ≤% | 13 | |||||||

| The tensile force at 2% elongation in the longitudinal direction is ≥ KN/m | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 |

| Tensile force at 2% elongation in the transverse direction KN/m | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 |

| Tensile force at 5% longitudinal elongation KN/m | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 |

| Tensile force at 5% elongation in the transverse direction KN/m | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 |

| Width m | 1-6 | |||||||