| Specification Model (Warp Strength kN/m) | Weft Strength (kN/m) ≥ | Elongation at Break (%) ≤ | Mass per Unit Area (g/m²) Ref. | CBR Puncture Strength (kN) ≥ | Remarks |

| 100 | 50 | 15% | Approx. 250 – 350 | 3.5 | General road base reinforcement |

| 150 | 75 | 15% | Approx. 350 – 450 | 5 | Moderate reinforcement applications |

| 200 | 100 | 15% | Approx. 450 – 550 | 7 | Highway, embankment reinforcement |

| 300 | 150 | 15% | Approx. 600 – 750 | 10 | Heavy-duty roads, reinforced walls |

| 400 | 200 | 15% | Approx. 800 – 950 | 14 | High steep slopes, large retaining walls |

| 500+ | As designed | 15% | > 1000 | As designed | Special major projects, custom-made |

High Strength Woven Geotextile

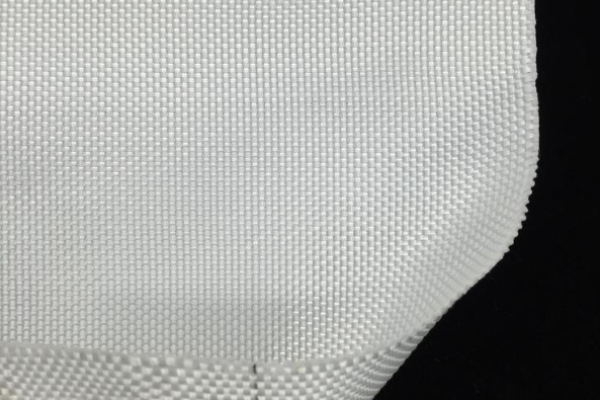

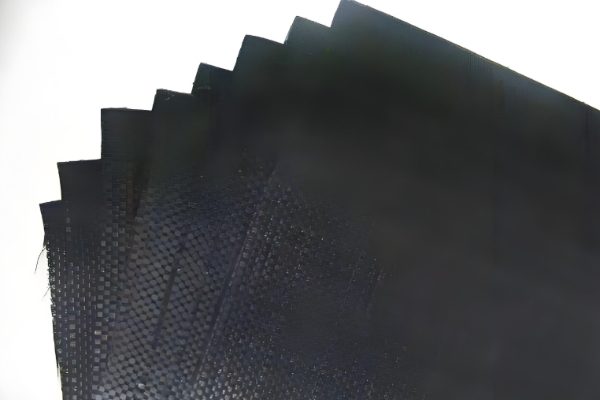

Material:High strength polypropylene (PP) or polyester (PET)

Feature:High tensile strength, low elongation, good friction coefficient

Application:Highways, railways, ports, airports

Shipping Method:logistics

Product Category:Geotextile Fabric,Woven Geotextile Fabric

Price:The price of high strength woven geotextile is not fixed and is influenced by various factors. For more details, please consult us.

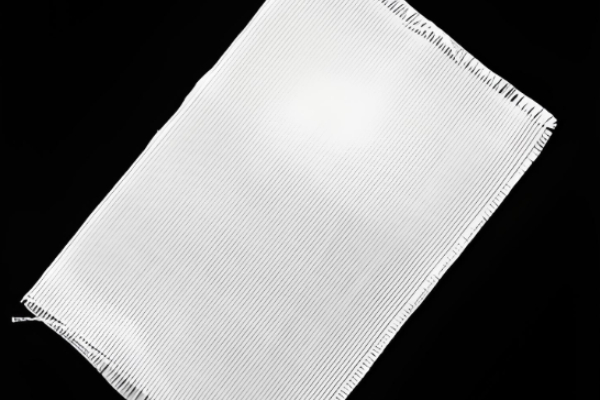

High-strength woven geotextile is a geosynthetic material composed of high-molecular polymers (primarily polypropylene PP or polyester PET) in the form of flat filament yarns, which are woven together on industrial looms according to specific specifications. Its most notable characteristics are extremely high tensile strength and low elongation in both the warp and weft directions, enabling excellent reinforcement, separation, and stabilization functions.

Performance

Excellent Mechanical Properties:

- High Tensile Strength and Low Elongation:This is the core performance feature of high-strength woven geotextiles.The tensile strength can range from 20 kN/m to over 400 kN/m,with the elongation at break typically controlled within 12%to 25%.This effectively distributes loads and restrains soil deformation.

- High Modulus:It exhibits high stiffness from the initial stages of loading,enabling it to provide immediate reinforcement.

Durability and Anti-Aging Properties:

- The incorporation of UV stabilizers and anti-aging agents into the raw materials ensures a long service life(potentially decades)when the geotextile is buried or covered.

- It offers excellent resistance to corrosion from common chemicals found in soil,such as acids,alkalis,and salts.

Separation and Filtration Functions:

- Although the aperture size of high-strength woven geotextiles is relatively small and uniform,it still allows water to pass along the plane of the fabric while effectively preventing the intermixing of soil and aggregate layers of different particle sizes,thereby maintaining their structural integrity.

Construction Convenience:

- Supplied in rolls,which are relatively lightweight,facilitating transportation,cutting,and installation.

Application

Reinforcement and Stabilization Engineering:

- Soft Soil Foundation Treatment:High-strength woven geotextiles are used in soft subgrades for highways,railways,ports,and airports.They enhance the bearing capacity of the foundation and reduce differential settlement through a reinforcement mechanism.

- Reinforced Retaining Walls/Slopes:Acting as tensile elements,they form a stable composite structure together with backfill soil,used for steep slopes,bridge abutments,etc.

Separation and Stabilization Engineering:

- Roadbed Engineering:High-strength woven geotextiles are installed between the roadbed and the subgrade to prevent the gravel cushion from penetrating into the soft soil,while simultaneously distributing loads evenly.

- Embankment and River Channel Improvement:They separate different construction materials in dams and prevent piping,thereby enhancing overall stability.

Other Applications:

- High-strength woven geotextiles are used as a protective layer for geomembranes(e.g.,HDPE geomembranes).

- Temporary road construction in harsh environments(e.g.,mining sites,construction access roads).