PVC Geomembrane

PVC Geomembrane Manufacturer: Shandong Lianjie – The leading geomembrane manufacturer in China. It is located in the High-Tech Development Zone of Tai’an City. Lianjie is a one-stop supplier of geosynthetics with 15 years of professional experience and multiple national certifications. Our PVC geomembranes include 20 mil,30 mil PVC geomembrane, and so on. We will customize the most professional one-stop PVC geomembrane solution for you according to your needs!

What is PVC Geomembrane

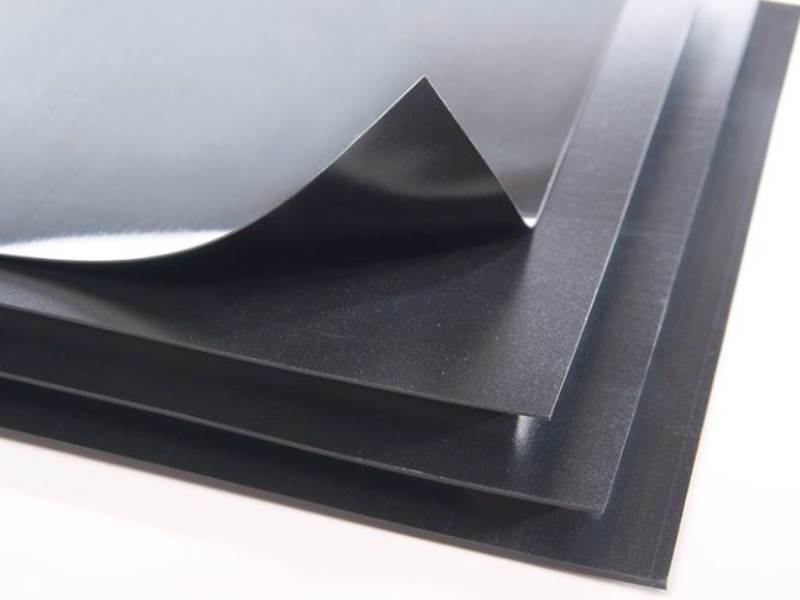

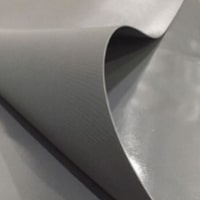

PVC geomembrane is a flexible impermeable membrane material primarily made from polyvinyl chloride (PVC) resin, which is plasticized and calendered with the addition of plasticizers, stabilizers, and other additives. It exhibits an extremely low permeability coefficient (typically ≤10⁻¹¹ cm/s), providing excellent impermeability that effectively prevents the leakage of liquids and gases. Additionally, this material possesses well-balanced mechanical properties, enabling it to accommodate uneven ground settlement. Its stable molecular structure endows it with superior UV resistance, aging resistance, and chemical corrosion resistance, ensuring long-term durability in complex environments.

Price of PVC Geomembrane

The market price of PVC geomembranes is not fixed or uniform; instead, it fluctuates within a dynamic range influenced by multiple factors. Currently, the mainstream price generally ranges from 8 yuan to 25 yuan per square meter.Its core pricing logic first depends on raw material costs and product specifications. Products made from new polyvinyl chloride (PVC) resin, high-quality plasticizers, and stabilizers perform better in key properties such as aging resistance, puncture resistance, and low-temperature anti-brittleness, and their costs are significantly higher than those using recycled materials or inferior additives. Meanwhile, the product’s thickness and weight per unit area are direct parameters affecting the unit price.

Our PVC Geomembrane for Sale

PVC Geomembrane Specification Parameter Table

Specific Parameter | Unit | Typical Value / Range | Remarks & Explanation |

|---|---|---|---|

Thickness | mm | 0.50 - 2.00 | Most common specifications are 0.75mm, 1.00mm, 1.50mm |

Mass per Unit Area | g/m² | 600 - 2500 | Positively correlated with thickness, a key factor in pricing |

Tensile Strength (MD/XD) | MPa/N | ≥10 | Measures resistance to tensile failure |

Elongation at Break (MD/XD) | % | ≥200 | Reflects material toughness and ability to accommodate deformation |

Tear Strength (MD/XD) | N | ≥40 | Characterizes resistance to local tearing and puncture |

CBR Burst Strength | kN | ≥1.5 | Indicates resistance to concentrated loads (e.g., from gravel) |

Permeability Coefficient | cm/s | ≤ 10⁻¹¹ | Core indicator, ensures excellent impermeability |

UV Resistance Strength Retention Rate (after UV exposure) | % | ≥80 | Evaluates anti-aging performance under outdoor exposure |

Low Temperature Bend Test | °C | No cracks at -20°C / -25°C | Ensures flexibility is maintained in low-temperature environments |

Dimensional Stability | % | ±2 - ±3 | Represents the change in length and width under thermal stress |

the Key Strengths of PVC Geomembrane

Excellent Impermeability

Extremely low permeability coefficient ensures effective containment of liquids and gases.

Outstanding Durability

UV, aging, and chemical corrosion resistance ensure long-term stability.

Easy Installation

Flexible material allows easy laying with reliable welded seams.

Mechanical Properties

High tensile and tear resistance accommodates ground deformation.

Latest Blog Posts

In infrastructure construction, slope protection, waterproofing, temporary works and other scenarios, Concrete

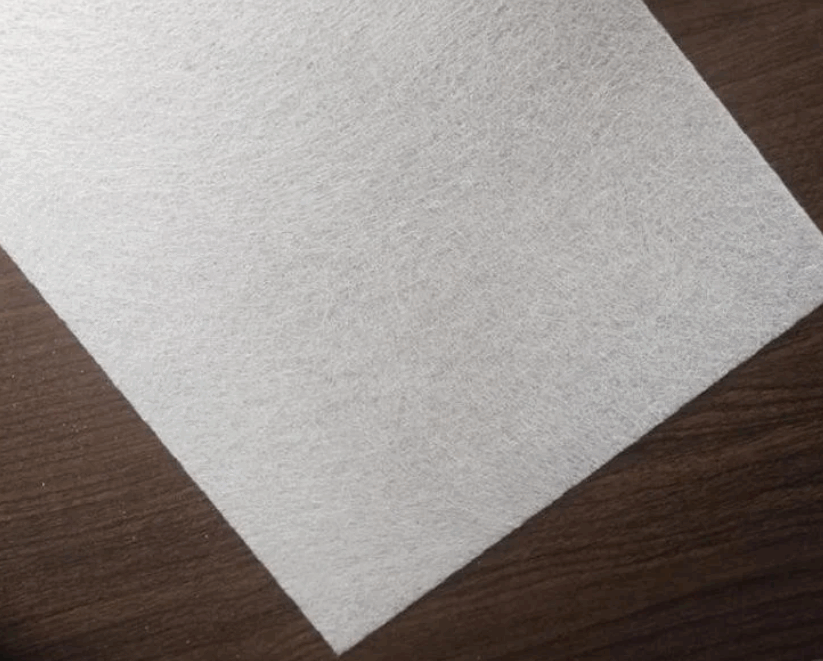

As a core category of geosynthetic materials, Filter Fabric Geotextile is a

In infrastructure projects such as roads, slopes, dams and soft soil foundations,

In civil engineering, water conservancy construction, environmental governance and other fields, waterproof

For households or commercial establishments with independent septic systems, clogging, poor drainage,

In fields such as agricultural cultivation, landscaping, and road maintenance, weed infestation

In the field of civil engineering, Concrete Geotextile, as a key geosynthetic

Gravel is widely used in landscape renovation scenarios such as patio paths,