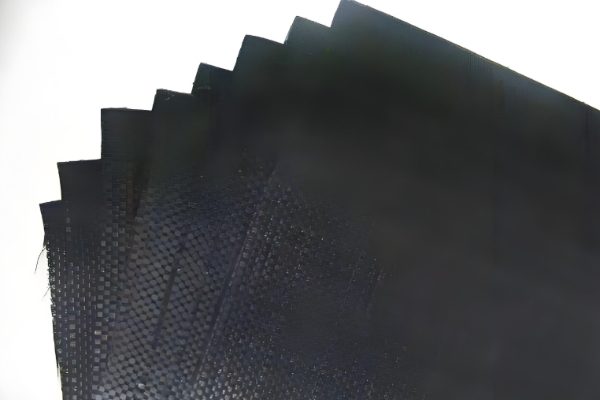

Woven Geotextile Fabric

Woven Geotextile Manufacturer:Shandong Lianjie – The leading geotextile manufacturer in China.It is located in the High-Tech Development Zone of Tai’an City. Lianjie is a one-stop supplier of geosynthetics with 15 years of professional experience and multiple national certifications.Our products include pp woven geotextile,geotextile woven filter fabric and so on. We will customize the most professional one-stop woven geotextile solution for you according to your needs!

What is Woven Geotextile Fabric

Woven geotextile is a type of geosynthetic material manufactured from polypropylene or polyester tapes using a conventional weaving process. It is characterized by its high tensile strength, low elongation, and excellent structural stability, exhibiting anisotropic behavior. Its primary functions are reinforcement and separation. It is widely used in applications such as soft ground improvement for roads and railways, reinforced soil retaining walls, and as a separation layer in subgrades, where it enhances soil integrity, distributes loads, and prevents material intermixing. Its hydraulic properties (e.g., permeability) are generally inferior to those of nonwoven geotextiles, making it unsuitable for primary filtration or drainage applications.

Woven Geotextile Fabric Prices

The price of woven geotextile is not fixed and is highly influenced by raw material costs (PP or PET), specifications, order volume, and market supply and demand.

Current market prices cover a wide range; for conventional specifications (e.g., with a mass per unit area of 100-200 g/m² and a tensile strength of 8-20 kN/m), the price generally falls between 2 and 6 RMB per square meter.

Products with higher strength, wider widths, or special features (such as UV resistance) command a higher price. Bulk orders typically qualify for volume-based discounts.

Our Woven Geotextile Fabric for Sale

Woven Geotextile Specification Parameter Table

Specification Name | Unit | Conventional Series (Low Strength) | Reinforcement Series (High Strength) | Notes |

|---|---|---|---|---|

Mass per Unit Area | g/m² | 100 - 200 | 200 - 400+ | Fundamental indicator affecting physical properties. |

Thickness | mm | 0.4 - 0.8 | 0.7 - 1.5 | Measured under 2kPa pressure. |

Tensile Strength | kN/m | - | - | Core mechanical property, specified in machine and cross-machine directions. |

- Machine Direction (MD) | kN/m | 10 - 20 | 30 - 100 | Strength along the roll length. |

- Cross Machine Direction (CMD) | kN/m | 10 - 18 | 25 - 80 | Strength along the roll width. |

Elongation at Break | % | ≤ 25 | ≤ 25 | Typically required to be ≤25% in both MD and CMD. |

CBR Burst Strength | kN | 2.0 - 4.0 | 4.5 - 11.0 | Indicates resistance to local puncturing. |

Apparent Opening Size (O₉₀) | mm | 0.07 - 0.2 | 0.2 - 0.5 | Controls soil retention and permeability. Less critical for reinforcement. |

Width | m | 3 - 6 | 3 - 6 | 4m, 5m, 6m are most common; wider widthsreduce field seams. |

Roll Length | m | 50 - 100 | 50 - 100 | Adjustable according to order requirements. |

the Key Strengths of Woven Geotextiles

High Strength

Sufficient strength and elongation retention in both dry and wet states

Corrosion Resistance

Ability to withstand corrosion from soils and water with varying pH levels over extended periods

Protective Function

Protects embankments from erosion caused by wind, waves, and rainwater

Separation

Woven geotextiles prevent the mixing of two types of soil.

What is Woven Geotextile Fabric Used for

Reinforces the soil beneath asphalt and gravel roads.

Prevents contamination of soil and groundwater by landfill leachate, ensuring the safety of the surrounding environment.

Protects slopes and embankments from soil displacement.

Strengthens backfill materials to ensure structural stability.

Woven VS Non Woven Geotextile

Woven Geotextile

Manufacturing Process

Produced by interlacing monofilament or multifilament yarns in warp and weft directions, similar to traditional textile weaving processes.

Key Properties

- High tensile strength and modulus

- Low elongation (typically less than 15%)

- Excellent UV resistance

- Relatively uniform pore size

- Lower permeability

Advantages

- Excellent separation and reinforcement functions

- Good long-term stability

- Strong chemical resistance

- Suitable for high-stress environments

Nonwoven Geotextile

Manufacturing Process

Produced by mechanically, thermally, or chemically bonding randomly arranged fibers without traditional weaving processes.

Key Properties

- High permeability and filtration capability

- Medium strength and elongation

- Greater thickness with good cushioning properties

- Isotropic (similar properties in all directions)

- Strong puncture resistance

Advantages

- Excellent filtration and drainage functions

- Good protection properties

- Easy installation

- Suitable for irregular surfaces

Frequently Asked Questions

Is woven geotextile permeable?

Yes, woven geotextiles are permeable, but their permeability has specific meanings and engineering applications.

Unlike non-woven geotextiles, whose primary function is vertical filtration, the permeability of woven geotextiles is mainly characterized by their in-plane water transmission capability (i.e., drainage along the plane of the fabric). They are manufactured by interlacing flat or filament yarns in a regular pattern, creating a stable, uniform pore structure. However, these pore sizes are typically relatively small.

How to install woven geotextile?

The installation of woven geotextiles must follow a professional sequence,with the core steps outlined below:

Subgrade Preparation: The installation surface must be level,compacted,and cleared of sharp objects like roots and stones.It should be free of standing water to create a solid,even foundation.

Unrolling and Placement: Unroll the material along the direction of construction,ensuring it lies flat and smooth without wrinkles.A slack of 1%to 1.5%should be maintained,allowing the fabric to conform to the subgrade without being stretched taut.

Seaming: The primary method is overlapping.The overlap width is typically 30-100 cm,determined by project specifications and subsoil conditions.The upstream sheet must overlap the downstream sheet.For projects requiring high reinforcement,sewing is an alternative.

Covering: After placement,the geotextile must be covered with fill material(e.g.,sand,gravel)promptly to prevent prolonged UV degradation.The initial layer of fill should be no less than 30 cm thick and compacted gently from the center outwards using light machinery to avoid damage from direct heavy equipment contact.

Key Takeaway: Immediate covering and protection,along with the specified initial lift thickness and light compaction,are critical.Standardized installation is fundamental to ensuring the geotextile performs its functions of reinforcement,separation,and drainage effectively.

Latest Blog Posts

Have you ever faced these frustrations:a gravel driveway that became uneven and

When constructing slope protection,reinforcing riverbanks,or building drainage channels,using riprap(rock armour)alone carries significant

This guide provides a comprehensive overview of geotextile materials,including basic concepts,types,a price

This article serves as a systematic guide to explain what geotextile filter

Imagine your beautifully laid paver driveway or patio,a significant investment of time

Why is non woven geotextile the preferred choice for French drain systems?

Explore our complete guide to geotextile road fabric. Learn about woven vs

Geotextile Fabric Retaining Wall.Discover why geotextile fabric is crucial for retaining wall